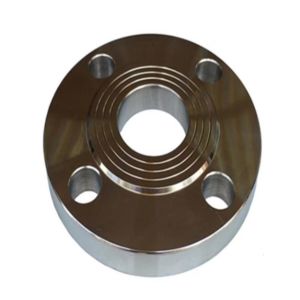

Kabby Flanges, a reputable manufacturer and supplier located in Abuja, Nigeria, specializes in top-notch Titanium Slip On Flanges that are built for high performance, durability, and precision. These flanges are designed for easy installation and alignment within piping systems, making them perfect for a variety of industrial uses. Crafted from high-grade titanium, they offer remarkable corrosion resistance, impressive strength, and long-lasting durability, even in tough conditions. Kabby Flanges is committed to ensuring that every product meets international standards, serving industries such as oil and gas, petrochemical, power generation, marine, and aerospace with dependable and efficient flange solutions.

The Titanium Slip On Flanges are produced using premium titanium grades like Grade 2 and Grade 5, which are celebrated for their excellent mechanical strength, lightweight characteristics, and outstanding resistance to corrosion. These flanges boast tensile strength between 350–900 MPa, along with excellent ductility and superior resistance to oxidation and chemical exposure. Their non-magnetic and low-density features make them perfect for applications that demand both high performance and reduced weight. Even under extreme pressure and temperature, Titanium Slip On Flanges remain stable, ensuring long-term operational efficiency.

| Trade name | Titanium Slip On |

| Titanium Slip On Flanges Standard | ASTM B381 / ASME SB381 ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges |

| Titanium Slip On Dimensions | B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN |

| Titanium Slip On Flanges Size | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000) |

| Titanium Slip On Flanges Class/Pressure |

|

| Flange Face Type | Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Titanium Slip On Flanges Marking | All Flanges are marked as follows: Grade, Standard, Thickness, Heat No. (Or according to the customer’s request.) |

Kabby Flanges, a leading supplier in Abuja, Nigeria, offers an extensive selection of Titanium Slip On Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

These flanges are widely utilized in industries that prioritize high strength and corrosion resistance while allowing for easy installation. They find common use in chemical processing, desalination plants, marine systems, and offshore oil and gas operations. Their slip-on design facilitates quick fitting and precise alignment, which helps cut down on installation time and costs. In the aerospace and power generation sectors, these flanges provide lightweight yet sturdy connections for critical systems. With their resistance to seawater, chlorides, and acidic environments, Titanium Slip On Flanges guarantee reliable performance and an extended service life in demanding industrial settings.

| Element | Titanium | Nitrogen | Carbon | Hydrogen | Iron | Oxygen | Residuals (each) | Residuals (total) |

| % | Balance | 0.03 max | 0.08 max | 0.015 max | 0.30 max | 0.25 max | 0.1 max | 0.4 max |

| 0.2% Proof Stress | Tensile Strength | Elongation | |

| MPa | MPa | % | |

| Annealed | 275-450 | 345 | 20 |

Yes, we offer custom sizes for Titanium Slip On Flanges to meet specific project needs. Our team at Kabby Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@kabbyflanges.com.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Kabby Flanges, All rights reserved