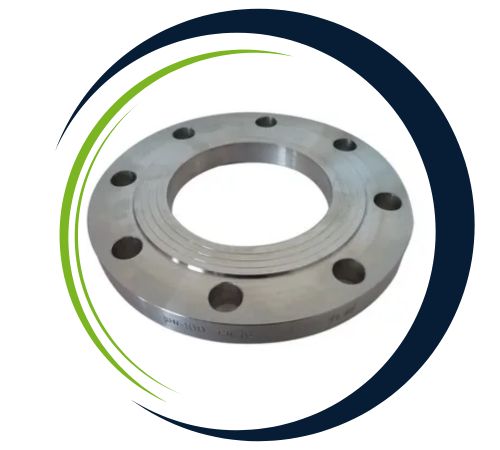

Kabby Flanges, a top-notch manufacturer and supplier located in Abuja, Nigeria, is all about crafting high-quality Super Duplex Steel Flanges. These flanges are celebrated for their incredible strength, resistance to corrosion, and long-lasting durability. Designed to thrive in tough conditions with high pressure, temperature, and corrosive substances, they’re built to perform reliably. Using cutting-edge technology and premium Super Duplex stainless steel, these flanges boast impressive resistance to pitting, crevice corrosion, and chloride stress cracking. Kabby Flanges is committed to ensuring that all their products meet international standards, catering to industries like oil and gas, petrochemical, desalination, marine, and power generation with trustworthy flange solutions.

Super Duplex Steel Flanges are crafted from top-grade materials like UNS S32750 and S32760, providing a fantastic blend of mechanical strength and corrosion resistance. They feature a unique dual-phase microstructure of austenite and ferrite, delivering tensile strength between 800–900 MPa and yield strength around 550 MPa. These flanges excel in resisting oxidation and chemical attacks, even in harsh acidic and chloride-rich environments. Their remarkable toughness, fatigue resistance, and dimensional stability make them perfect for critical and high-stress applications.

| Specifications | : | ASTM A182 / ASME SA182 |

| Size | : | 1/8″ NB TO 24″ NB |

| Standards | : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Grades | : | S32750 / S32760 / S32950 |

Kabby Flanges, a leading supplier in Abuja, Nigeria, offers an extensive selection of Super Duplex Steel Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

| % | ASTM A182 Super Duplex UNS S32750 And UNS 32760 Flanges |

| C | 0.03 maximum |

| Mn | 1.5 |

| Mo | 3.0-5.0 |

| Ni | 5.5-8.0 |

| N | 0.2-0.35 |

| Si | 0.8 |

| P | 0.035 |

| S | 0.02 |

| Cr | 24-26 |

| Cu | 0.5-3.0 |

| Tensile Strength (in MPa) | 770 |

| A5 Elongation (in %) | 25 |

| Proof Stress 0.2% (in MPa) | 550 |

You’ll find Super Duplex Steel Flanges widely used in industries where top-tier strength and corrosion resistance are a must. They’re commonly found in offshore oil rigs, chemical processing plants, desalination systems, marine applications, and power generation facilities. In pipelines and pressure vessels, they guarantee leak-proof, durable, and long-lasting connections, even under extreme conditions. Their ability to endure aggressive environments while minimizing maintenance costs makes them invaluable for industrial operations. With their unmatched mechanical and anti-corrosive properties, Super Duplex Steel Flanges offer exceptional reliability, performance, and longevity in demanding applications.

| Normal Pipe Size | Flanges Diameter (‘O’) | Diameter of (B.C.) ‘A’ | Diameter of (B.H.) ‘D’ | Holes Number | Flanges Wall Thickness ‘C’ | Diameter (Flanges) at Weld Bevel | (Flanges) Diameter of Hub ‘E’ | Length Of Through Hub | Bore (‘B’) | Diameter of (RF) R | Depth of Socket Weld F | Threading Length | ||||

| SORF/ SWRF (Y) | WNRF (Y) | Lap Joit (Y) | SORF/ SWRF (B) | Lap Joit (B) | ||||||||||||

| 1/2” | 15 | 95.2 | 66.7 | 15.9 | 4 | 14.3 | 21.3 | 38.1 | 22.2 | 52.4 | 22.2 | 22.3 | 22.9 | 34.9 | 9.5 | 15.9 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/4” | 20 | 117.5 | 82.5 | 19.0 | 4 | 15.9 | 26.7 | 47.6 | 25.4 | 57.1 | 25.4 | 27.7 | 28.2 | 42.9 | 11.1 | 15.9 |

| 1” | 25 | 123.8 | 88.9 | 19.0 | 4 | 17.5 | 33.5 | 54.0 | 27.0 | 61.9 | 27.0 | 34.5 | 35.0 | 50.8 | 12.7 | 17.5 |

| 1 | 32 | 133.3 | 98.4 | 19.0 | 4 | 20.6 | 42.2 | 63.5 | 28.6 | 66.7 | 28.6 | 43.2 | 43.7 | 63.5 | 14.3 | 20.6 |

| 1 | 40 | 155.6 | 114.3 | 22.2 | 4 | 22.2 | 48.3 | 69.8 | 31.7 | 69.8 | 31.7 | 49.5 | 50.0 | 73.0 | 15.9 | 22.2 |

| 2” | 50 | 165.1 | 127.0 | 19.0 | 8 | 25.4 | 60.4 | 84.1 | 36.5 | 73.0 | 36.5 | 62.0 | 62.5 | 92.1 | 17.5 | 25.4 |

| 2 | 65 | 190.5 | 149.2 | 22.2 | 8 | 28.6 | 73.1 | 100.0 | 41.3 | 79.4 | 41.3 | 74.7 | 75.4 | 104.8 | 19.0 | 28.6 |

| 3” | 80 | 209.5 | 168.3 | 22.2 | 8 | 31.8 | 88.9 | 117.5 | 46.0 | 82.5 | 46.0 | 90.7 | 91.4 | 127.0 | – | 30.2 |

| 3 | 90 | 228.5 | 184.2 | 22.2 | 8 | 34.9 | 101.6 | 133.4 | 49.3 | 85.7 | 49.3 | 103.4 | 104.1 | 140.0 | – | 31.7 |

| 4” | 100 | 273.0 | 215.9 | 25.4 | 8 | 38.1 | 114.3 | 152.4 | 54.0 | 101.6 | 54.0 | 116.1 | 116.8 | 157.2 | – | 33.3 |

| 5” | 125 | 330.2 | 266.7 | 28.6 | 8 | 44.4 | 141.2 | 188.9 | 60.3 | 114.3 | 60.3 | 143.8 | 144.5 | 185.7 | – | 36.5 |

| 6” | 150 | 355.6 | 292.1 | 28.6 | 12 | 47.6 | 168.4 | 222.2 | 66.7 | 117.5 | 66.7 | 170.7 | 171.4 | 215.9 | – | 39.7 |

| 8” | 200 | 419.1 | 349.2 | 31.7 | 12 | 55.6 | 219.2 | 273.0 | 76.2 | 133.3 | 76.2 | 221.5 | 222.2 | 269.9 | – | 44.4 |

| 10” | 250 | 508.0 | 431.8 | 34.9 | 16 | 63.5 | 273.0 | 342.9 | 85.7 | 152.4 | 111.2 | 276.3 | 277.4 | 323.8 | – | 49.2 |

| 12” | 300 | 558.8 | 488.9 | 34.9 | 20 | 66.7 | 323.8 | 400.0 | 92.1 | 155.6 | 117.3 | 327.1 | 328.2 | 381.0 | – | 55.6 |

| 14” | 350 | 603.2 | 527.0 | 38.1 | 20 | 69.9 | 355.6 | 431.8 | 93.7 | 165.1 | 127.0 | 359.1 | 360.2 | 412.7 | – | 57.1 |

| 16” | 400 | 685.8 | 603.2 | 41.3 | 20 | 76.2 | 406.4 | 495.3 | 106.4 | 177.8 | 139.7 | 410.5 | 411.2 | 469.9 | – | 63.5 |

| 18” | 450 | 742.9 | 654.0 | 44.4 | 24 | 82.6 | 457.2 | 546.1 | 117.5 | 184.1 | 152.4 | 461.8 | 462.3 | 533.4 | – | 68.3 |

| 20” | 500 | 812.8 | 723.9 | 44.4 | 24 | 88.9 | 508.0 | 609.6 | 127.0 | 190.5 | 165.1 | 513.1 | 514.3 | 584.2 | – | 73.0 |

| 24” | 600 | 939.8 | 838.2 | 50.8 | 24 | 101.6 | 609.6 | 717.5 | 139.7 | 203.2 | 184.1 | 615.9 | 615.9 | 692.1 | – | 82.5 |

Yes, we offer custom sizes for Super Duplex Steel Flanges to meet specific project needs. Our team at Kabby Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@kabbyflanges.com.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Kabby Flanges, All rights reserved