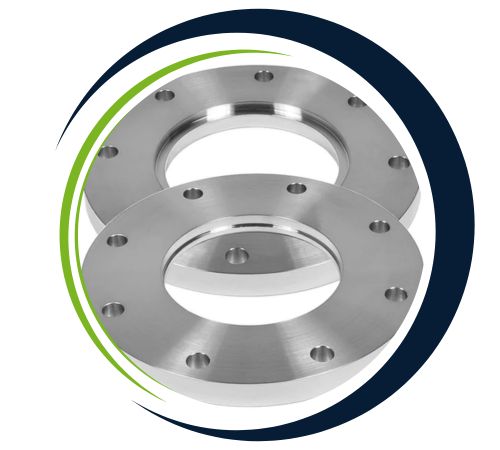

Maduka Metals, a well-respected manufacturer and supplier based in Abuja, Nigeria, specializes in high-quality Monel Slip On Flanges that are built for strength, durability, and resistance to corrosion. These flanges are designed for easy installation, allowing pipes to slide right into the flange bore before welding, which guarantees a secure and leak-proof connection. Crafted from premium-grade Monel alloy, they’re perfect for applications that involve high pressure, temperature, and corrosive environments. Maduka Metals is committed to providing precision-engineered Monel Slip On Flanges that adhere to international standards, serving industries like oil & gas, petrochemical, marine, and power generation.

Monel Slip On Flanges are primarily made up of nickel (around 63%) and copper (30–34%), along with small amounts of iron, manganese, and silicon. This unique nickel-copper blend offers exceptional resistance to corrosion from seawater, acids, and alkalis. They boast impressive mechanical properties, featuring a tensile strength of about 550 MPa and a yield strength of roughly 240 MPa. The remarkable toughness and hardness of Monel make these flanges perfect for high-stress situations. They maintain their mechanical integrity and performance even when faced with extreme temperature and pressure changes.

| Specification | ASTM B564 / ASME SB564 |

|---|---|

| Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MAlloy S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| PRESSURE Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| PRESSURE Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS 15 NB (1/2″) to 200 NB (8″) Equal and Reducing Configurations |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Premonel machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange B.S: BS4504 , BS3293, BS1560, BS10 AS 2129: Table D; Table E; Table H ANSI B16.5, ANSI B16.47 Series A & B, MAlloy SP44, ASA, API-605, AWWA, Custom Drawings ANSI : ANSI B16.5, ANSI B16.47(API605), MAlloy SP44, ANSI B16.36, ANSI B16.48 ANSI B16.5, ANSI B16.47, MAlloy SP44, ANSI B16.36, ANSI B16.48 American standard (ANSI) German (DIN) British standard (BS) DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |

| Grades | Monel 400, K500 |

Kabby Flanges, a leading supplier in Abuja, Nigeria, offers an extensive selection of Monel Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

Monel Slip On Flanges are widely utilized in industries that require high levels of corrosion and heat resistance. They’re ideal for connecting pipes in chemical processing facilities, marine engineering projects, offshore oil drilling platforms, and desalination plants. These flanges also find applications in power generation, hydrocarbon processing, and heat exchangers, where reliability and strength are essential. Their slip-on design makes installation and alignment a breeze, making them a go-to choice for systems that need both flexibility and durability. In summary, Monel Slip On Flanges provide safe, long-lasting, and efficient performance in demanding industrial environments.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Monel 400 | 2.4360 | N04400 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

| Monel K500 | 2.4375 | N05500 | – | – | – | – | – |

Yes, we offer custom sizes for Monel Slip On Flanges to meet specific project needs. Our team at Kabby Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@kabbyflanges.com.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Kabby Flanges, All rights reserved